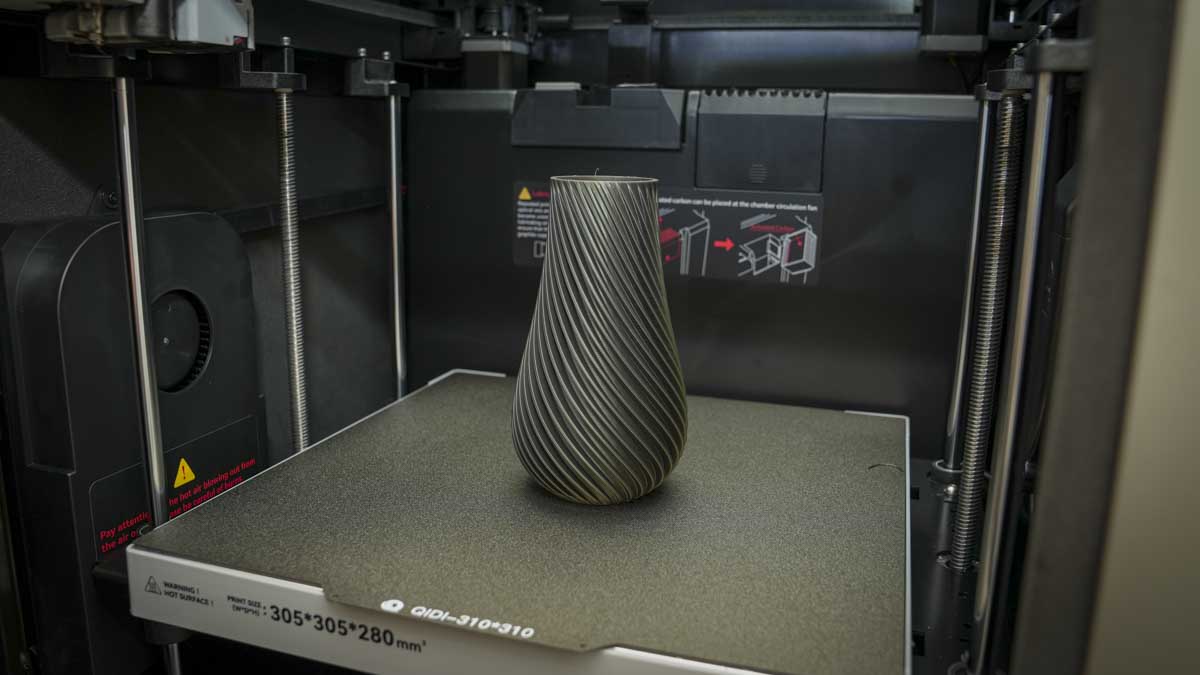

The QIDI X4 Plus builds on the solid design and technology we’ve previously seen from the company’s machines, yet here in the X4 Plus, we have something even more refined. The metal and glass build not only looks stylish but also reflects the business and education sector it is aimed at. It’s certainly one of the best 3D printers when it comes to its design. But how does it operate?

The fully enclosed X4 Plus with high-temperature tool head has been designed to cater to users who need a machine that offers a safe working enclosure for use in businesses and education, with a heated inner chamber that enables warp-free printing for advanced materials such as PA-CF, PET-CF, Nylon, and ABS.

The structure of the machine offers a bigger-than-average print area, enabling large-scale prints to be completed in single sessions, with a variety of built-in features that allow the machine to balance speed with quality perfectly.

While it does offer the latest COREXY mechanics powered by the latest Klipper V1.2 and a camera, the AI integration that we’ve seen on other machines has yet to be included. The build quality and design reflect the pricing of this impressive machine, but with rivals adding those AI features as well as other advanced printing capabilities, can this large yet slightly reserved 3D printer hold its ground?

QIDI X4 Plus: Design

The QIDI X4 Plus is a large and relatively weighty machine due to the high-quality metal and glass construction that helps to elevate the quality above the QIDI Q1 Pro that we looked at earlier in the year. This build is in line with the superb Creality K1C (check out our review) and BambuLabs X1 Carbon (read our review), and here again, we have a machine that at the base level compares extremely well, if slightly pared back on some features.

While the machine is large and really requires two people to lift it comfortably, there are two carry handles neatly inlaid into the top. These are a huge help when moving it around a studio, for instance, and likewise in professional settings or classrooms where items are moved around on a regular basis; these handles do help to make life a little easier.

The build is a standout feature and really helps to set off the build quality and style of the machine. Being fully enclosed also enables the second-generation active heating chamber that allows the inner space to reach temperatures of up to 65ºC in around eight minutes.

The solid build of the casing is reflected in the internal construction with a sturdy dual Z-axis design which, when coupled with the solid construction and weight, creates an ideal printing environment that helps to minimise vibrations and movement.

Controlling the machine is the now standard LCD screen on the front. This 5-inch model is fully touch-screen and enables you to quickly navigate settings and options as well as start and stop prints. As ever, there’s also the option for Wi-Fi and Ethernet, as well as a more traditional USB stick for transferring files to the machine.

While the structure is fully enclosed, when it comes to printing PLA and other materials that fare better in an open frame environment, both the front of the machine as well as the top can be removed to give easy access and allow airflow.

QIDI X4 Plus: Features

Specs

Print Technology: Fused Deposition Modeling (FDM)

Build Area: 305 x 305 x 280 mm

Minimum Layer Resolution: 50 microns

Maximum Layer Resolution: 400 microns

Dimensions: 505 x 487 x 550 mm

Weight: 27 kg

Bed: Heated, up to 120°C

Print Surface: Dual-sided textured PEI plate

Software: QIDI Studio, compatible with PrusaSlicer, Orca

Materials: PLA, ABS, ASA, PETG, TPU, carbon/glass fibre composites

Print Speed: Up to 600 mm/s

To give you an idea of the size of the machine, it measures 505x487x550mm and weighs 32kg. This equates to an impressive print area of 305x305x280mm—more than large enough for most prints.

The entire enclosure, with the door, closed and the top lid in place is fully enclosed. It offers an active heating chamber, which is used when printing with advanced materials such as ABS and helps to minimise warping.

One of the X4 Plus’s key features is its active heating chamber, which, until recently, was relatively unheard of for printers in this price range and market. The purpose of the heated chamber is to reduce warping when printing materials like ABS and nylon. Essentially, before the printing starts, the chamber is heated to the desired temperature, say 65ºC, and then throughout the print process, that heat is maintained. The heated chamber is coupled with a 370°C hotend, which enables you to print with high-temperature materials like PPS-CF and PA-CF without needing to change the nozzle or tool head.

Alongside the newer features are some that we’ve come to expect on machines generally, such as the hands-free automatic bed levelling, which uses dual sensors, including a piezoelectric sensor beneath the hotbed, to ensure perfect first-layer adhesion. The direct extruder is designed to keep up with the COREXY mechanics and offers a maximum print speed of 600 mm/s.

In addition to the hardware, the software has also seen a major update with the latest version of QIDI Studio, once again offering fast slicing times and full integration with Klipper firmware. However, if you’re already using another slicer and don’t want to switch, the hardware fully supports third-party slicers like PrusaSlicer.

QIDI X4 Plus: Performance

What really stood out about the QIDI Q1 Pro was the print quality and dimensional accuracy, and again, here, the QIDI X4 Plus impresses with speed and accuracy.

From the outset, as the machine is lifted from the box, the leap in quality is instantly apparent. High-quality metal and glass construction marks a huge difference between this machine and the lower-priced Q1 Pro. Set-upSet-up time is extremely quick. A few securing bolts need to be removed along with the door handle, and you’re pretty much set to go.

In the initial set-up, there are two small points to highlight. The first is that the fixing for the LCD onto the top of the machine is a little loose, and while it stays in place during general use, there were a couple of occasions where, for one reason or another, it was nudged and came loose or was pushed askew. The other point is the initial filament feed, which requires you to push the filament into the machine—this was standard for machines a year or two ago, but it feels a little less refined than the majority of new machines. However, neither of these points has any effect on the prints.

As is now standard with most machines, the calibration process is fully automated. A single click on the calibration you wish the machine to run, and off it goes. No further adjustment is needed before you start to print.

Laying out the models within QIDI Studio is fast and easy, and exporting to the machine was also straightforward, with a few choices for how to connect to the machine. In this test, for ease of use, most of the connections were made through the USB stick and manual transfer. However, the LAN and Wi-Fi connections were also tested. The LAN connection is the easiest, with the machine appearing on the network, then the IP address recorded, and you’re connected. A similar process is used for the Wi-Fi connection, and again, this proved robust using the Eero wifi network hub.

On the machine itself, most things are self-contained, such as the calibration, and the machine once again collects excess filament at the back, which is something to watch. One of the major points of the machine is the large touch screen, which is impressive both in size and in the quality of the UI. However, while this screen is fast to respond and navigate through settings, there are occasions when switching from one model preview to another when the preview image lags. However, this isn’t too uncommon.

When it came to the actual print quality, once again, this is where the QIDI machine absolutely excels. The exterior wall quality is just about as smooth as any machine we have used, and overall print times were excellent. When it comes to the complexity of the prints, the printer once again highlights its abilities, and that active chamber allows you to print just as well with more advanced materials as it does with PLA.

During the test, we had a few issues with print bed adhesion at the beginning with some of the jointed models. However, after cleaning the bed and changing the filament, the problem was resolved. It’s worth pointing out that there isn’t any form of object or spaghetti detection, and the camera is for capturing time-lapse images only.

Overall, the print quality is excellent, with the cooling system kicking in and doing its job to ensure the highest-quality prints. After checking some of the primitive models for colour consistency, the results were again excellent, further highlighting the power of the fans. The results were directly comparable to those of the PRUSA MK4 and BambuLabs X1 Carbon.

Once the prints have finished, extracting them from the print platform is nice and easy, with most releasing completely once the platform has cooled. The only other thing you should do after the prints finish is give a quick clean behind the machine to clear away any excess filament that has been ejected during the print process at the back of the machine.

QIDI X4 Plus: Print quality

Dimensional accuracy – score of 5

Target 25 = X: 24.94mm / 0.06mm Error | Y: 25.05mm / 0.05mm Error

Target 20 = X: 19.95mm / 0.05mm Error | Y: 19.97mm / 0.03mm Error

Target 15 = X: 14.90mm / 0.1mm Error | Y: 14.94mm / 0.06mm Error

Target 10 = X: 9.90mm / 0.1mm Error | Y: 9.90mm / 0.1mm Error

Target 5 = X: 4.95mm / 0.05mm Error | Y: 4.98mm / 0.02mm Error

X Error Average = 0.072

Y Error Average = 0.052

X&Y Error Average = 0.062

Fine Flow Control – score of 5

Fine Negative Features – score of 5

Overhangs – score of 4

Bridging – score of 5

XY resonance – score of 2.5

Z-axis alignment – score of 2.5

Adding up the totals gives a final score of 29 out of 30.

QIDI X4 Plus: Final verdict

The QIDI X4 Plus is once again a great machine, with a huge step up in quality thanks to the all-metal and glass build. The size of the machine also places it at the mid to large end of the market, and with solid overall performance, it really doesn’t fail to impress with easy use and decent prints, featuring excellent surface quality and dimensional accuracy.

One thing to note about the machine is that firmware updates pushed out during the review also enhanced some of the features, which is good to see.

At present, QIDI Studio, while good, is only available for PC systems. However, the machine is fully compatible with PRUSA Slicer, and the Mac version is available on the companies Github site. It’s also worth noting that, while not yet available, a multi-filament accessory will soon arrive for the system, further elevating the printer.

Overall, the machine is a superb option for small businesses and education, where a fully enclosed machine capable of printing high-quality prints at speed is required. It can print with most common materials and features a high hotend temperature and a heated chamber, which just adds to its potential.

Should You Buy the QIDI X4 Plus?

| Row 0 – Cell 0 | Row 0 – Cell 1 | Row 0 – Cell 2 |

| Value: | Priced competitively for its features, but lacks AI seen in rivals. | 4.5 |

| Design: | Robust metal and glass build with excellent durability, though bulky. | 4.5 |

| Features: | Advanced material support, heated chamber, but UI is slightly sluggish. | 4 |

| Performance: | Exceptional print quality, high-speed printing, and impressive dimensional accuracy. | 5 |

| Total: | An ideal choice for businesses and education, combining precision, speed, and versatility. | 4.5 |

For more crafting tools, we reviewed the best laser engravers